Telefunken Italia - model "Mignonette MF" - 1a Serie

JAN 2023 - restoration notes.

I don't want to bore you with information that is already available on the net about radio restorations and/or about this particular radio model.

I just want to share my restoration notes and annotated schematic.

This radio has the chassis directly connected to the power line.

There is a very HIGH risk of electrocution - use an isolation transformer when working with this kind of old radios.

Please note the use of an auto-transformer that imply no isolation from mains (!!) and as the power switch is directly connected to the power line. There is no fuse!

Everyone putting his hands into this chassis must know what he is doing!!

I started replacing all paper caps and the 3 electrolytics.

Then I replaced all the resistors that measured way out of specs. Some of them are unreachable (left alone).

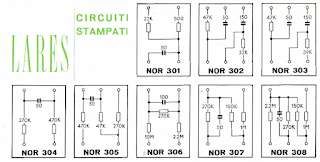

This Italian radio makes use of one of the first attempts to integrate components on a single "chip": they are LARES boards.

Here are few examples:

|

| Excerpt from LARES manual |